Table of Contents

The Definition of Printed Quartz

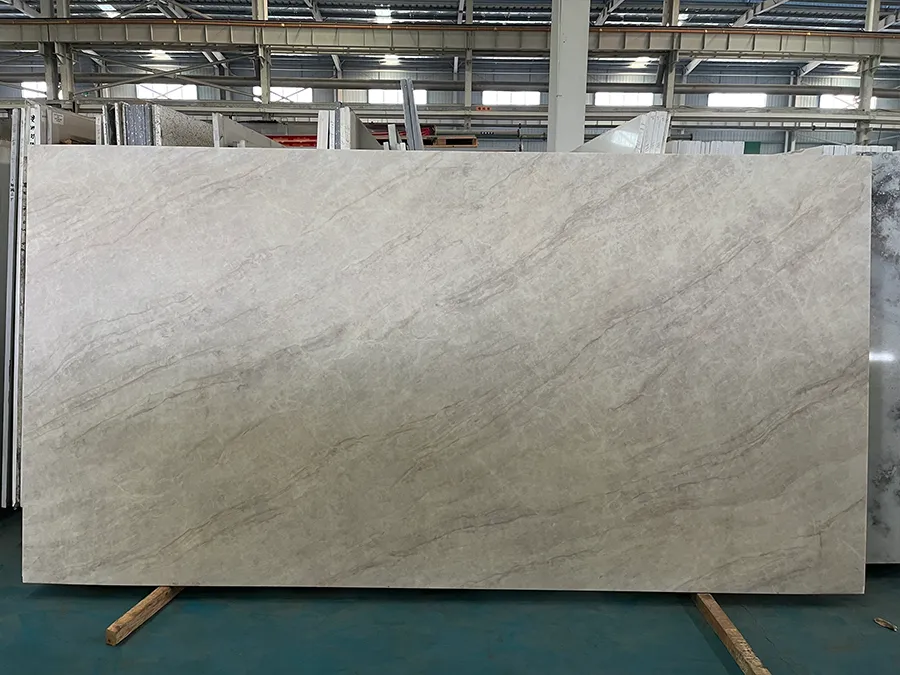

Printed quartz is one of artificial quartz that uses high-temperature ink infusion technology, intricate patterns are permeated directly into the surface of a pure white quartz base. This process eliminates the need for labor-intensive manual layout work, such as aligning veining or matching slabs, while delivering a flawless finish. Imagine transforming a plain white quartz slab into a masterpiece resembling natural marble, granite, or even abstract art—all within minutes. Printed quartz countertops achieve precisely this.

One of the standout advantages of printed quartz countertops is their customization potential. Whether you’re designing a modern kitchen backsplash or a bold statement island, the ability to tailor patterns, colors, and textures to your exact vision opens endless possibilities. Unlike traditional quartz, which relies on pre-mixed pigments, printed quartz uses advanced digital printing to replicate even the most complex designs with photorealistic accuracy.

Printed Quartz Slabs: Versatility in Design and Application

Printed quartz slabs are redefining how designers and homeowners approach surface materials. The process begins with a high-quality engineered quartz base, composed of 90–95% natural quartz crystals and resin binders. A specialized printer then applies vibrant, fade-resistant inks that penetrate the slab under high pressure and heat. The result? A seamless fusion of color and stone that resists scratching, staining, and UV damage.

This technology shines in projects requiring large-format consistency. For example, a Taj Mahal printed quartz slab can mimic the soft, ethereal veining of premium natural marble without the fragility or maintenance demands. Applications extend beyond countertops to wall cladding, flooring, and even furniture, making printed quartz slabs a versatile choice for residential and commercial spaces.

Printed Quartz vs. Quartz: Weighing the Pros and Cons

To understand printed quartz’s value, it’s essential to compare it to traditional quartz.

Traditional Quartz

• Pros: Naturally non-porous, scratch-resistant, and available in a range of colors and patterns.

• Cons: Limited to factory-mixed designs; bold patterns may show seams in large installations. Higher-end veined styles (e.g., Calacatta) come at a premium price.

Printed Quartz

• Pros: Unlimited design flexibility (custom luxury marble looks), seamless large-format printing, and cost-effective replication of luxury stone aesthetics.

• Cons: While durable, the printed layer is surface-deep; deep scratches might reveal the white base. However, advancements in full-body printing are mitigating this.

For designers prioritizing unique aesthetics without compromising on quartz’s durability, printed quartz often wins.

The Rise of 3D Printed Quartz Technology

3D printed quartz represents the next leap in surface innovation. Unlike conventional printing, 3D printed technology builds layers of material to create texture and depth, adding a tactile dimension to designs. Imagine a countertop with raised geometric patterns or a backsplash mimicking the grooves of natural travertine—all achievable without manual carving.

This method is particularly valuable for intricate projects, such as replicating the layered effect of sedimentary stone or embedding metallic accents. While still emerging, 3D printed quartz bridges the gap between flat visuals and multidimensional artistry.

Full Body Printed Quartz: Depth and Durability Combined

A common concern with printed surfaces is wear over time. Full-body printed quartz addresses this by infusing pigments throughout the entire slab, not just the top layer. This means edges, cuts, and even accidental chips maintain the design’s integrity. For high-traffic areas like kitchen islands or commercial bars, full-body printing ensures longevity without sacrificing aesthetics.

Taj Mahal Printed Quartz: Popular Choice for Countertops

The Taj Mahal printed quartz exemplifies how this technology replicates iconic natural stones. Named after the famed Taj Mahal marble, this design features soft gray veining on a bright white background, creating an airy, luxurious feel. Unlike natural marble, however, printed Taj Mahal quartz resists etching from acids (think lemon juice or vinegar) and requires no annual sealing—making it ideal for busy kitchens.

Cost Considerations: Is Printed Quartz Right for You?

When evaluating price, printed quartz often falls between standard quartz and premium natural stones like marble. Custom designs may incur additional costs, but the savings in labor (no need for artisan layout work) and maintenance can balance the investment. For example, a Taj Mahal printed quartz backsplash could cost 20–30% less than genuine marble while offering superior durability.

Final Thoughts: The Printed Quartz Advantage

Printed quartz is not just a trend—it’s a paradigm shift in surface design. By merging the strength of engineered quartz with limitless artistic potential, it empowers homeowners and designers to break free from the constraints of natural stone. Whether you’re drawn to the hyper-realism of 3D printed quartz or the practicality of full-body slabs, this material offers a compelling blend of beauty, durability, and innovation.

As the industry evolves, expect printed quartz to push boundaries further, blurring the line between art and architecture. For your next project, ask yourself: Why settle for ordinary when you can print extraordinary? Choose LBC printed quartz with various colors now!